NKCS ANCILLIARIES & SPARES:

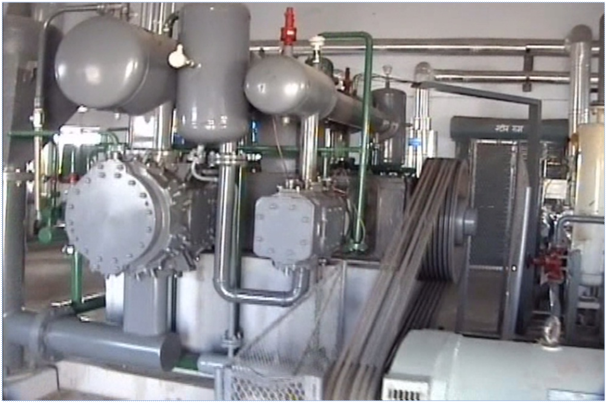

1. AIR COMPRESSOR :

Multi- stage, horizontal, positive displacement piston type with sight glass for indication of oil lubrication for each stage complete with fly wheel, Inter coolers including Foundation bolts, Motor, Motor pulley, V-bolts, Belt-Guard, Motor Starter and slide rails.

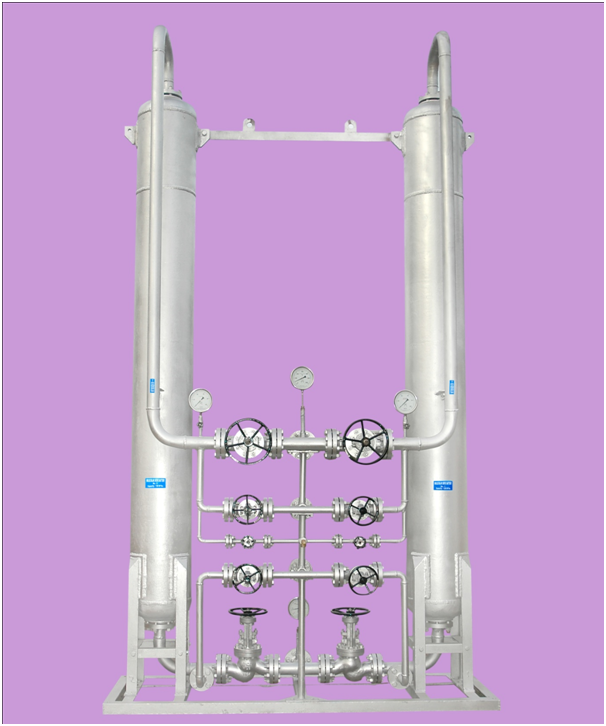

2. N.K.C.S. MOLECULAR SIEVE BATTERY SETUP :

It consists of 2 Nos. M. S. vessels inter connected with pipeline of Nitrogen and Air, heater for regeneration, temperature sensor and control panel with automatic controls. Each vessel of Molecular Battery is filled with molecular sieve of 1.5/3 mm type 13-X. This assist in the removal of moisture, carbon di- oxide, traces of Acetylene and other hydrocarbons present in the process air.

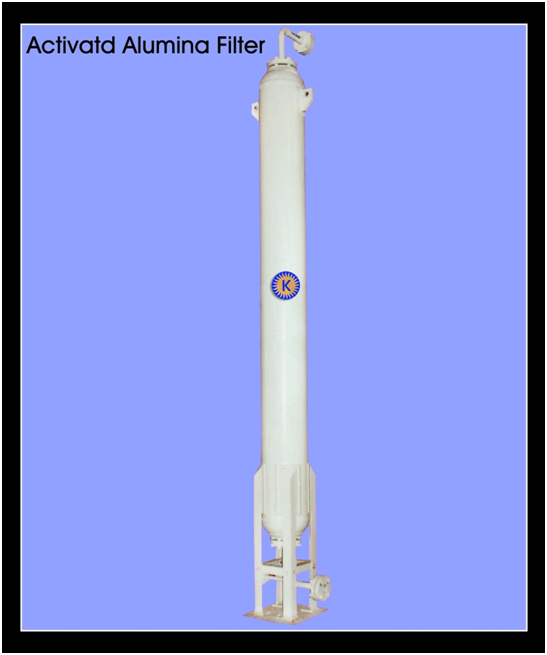

3. ACTIVATED ALUMINA FILTER:

This equipment is made of M. S. capsule shape vessel with activated Alumina with 2 Nos. S.S. Net filter insides this assist absorption of Hydrocarbons in the process air.

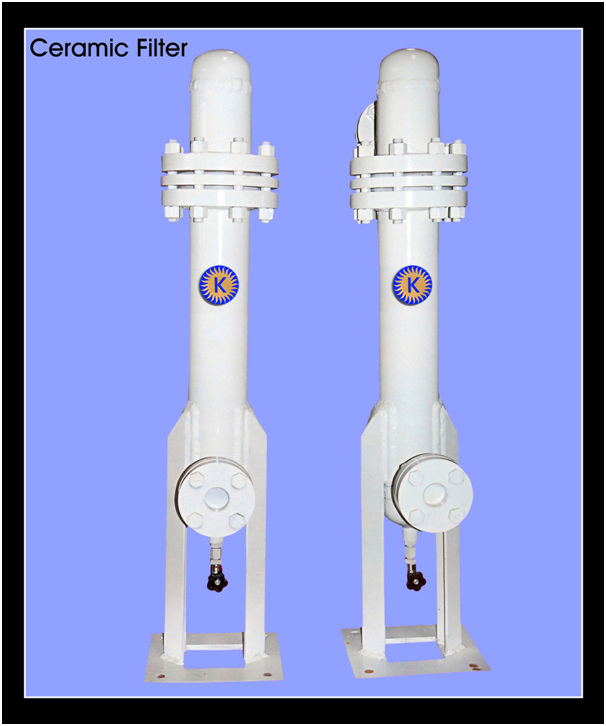

4. CERAMIC FILTER:

This equipment is made of M. S. and is cylindrical in shape. It consists of micro dust filter one before Molecular Battery and one other battery to avoid entry of dust to the A. S. U.

5. MOISTURE SEPARATOR :

It is capsule shape vessel made M. S. duly fitted with drain valves for removal of Moisture present in the process air.

6. CASCADE COOLER:

NKCS Cascade cooler is specially designed container consisting of high pressure M. S. Coils in two separate chambers. The Process air the passes through this cooler is cooled through incoming Nitrogen from A.S.U. These coils are immersed in water, level indicator.

7. CYLINDER FILLING MANIFOLD:

For filling high-pressure Oxygen or Nitrogen into cylinders. It consists of main high-pressure isolation valve and pigtail connection with individual regulation valve, pressure gauges, and safety relief valve and buffer manifolds.